What does the Payne Effect mean and how to measure it?

The Payne effect is a classic (and very important) phenomenon in filled rubber materials, especially those reinforced with carbon black or silica.

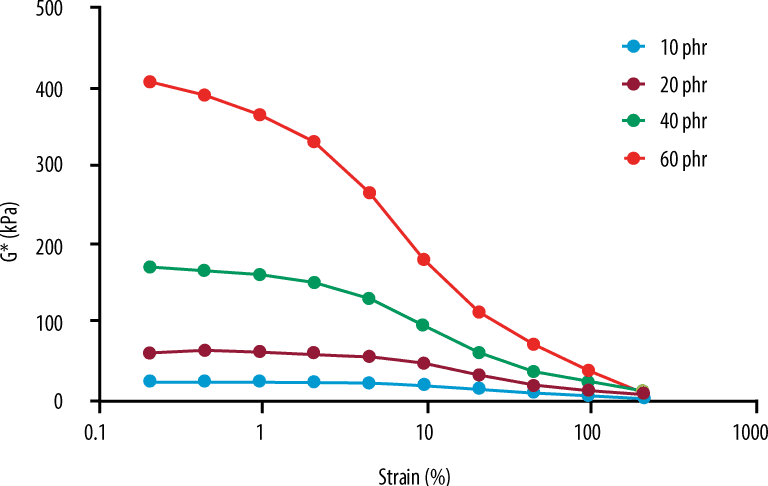

In short: when you cyclically deform a filled rubber at small to moderate strains, its storage modulus (G′) drops as strain amplitude increases. That strain-dependent softening is the Payne effect.

Image from: https://www.rubber-testing.com/products/moving-die-rheometer/d-rpa-3000

What’s actually happening

In filled rubbers, you don’t just have polymer chains—you also have a filler network:

Filler particles (carbon black, silica) form weak, physical connections with each other.

At very small strains, this filler–filler network is intact → high stiffness (high G′).

As strain increases:

The filler network progressively breaks down

Rubber becomes softer

G′ decreases, while loss modulus (G″) often increases

This breakdown is reversible: if you reduce the strain and let the material rest, the filler network partially reforms.

How to measure the Payne effect

Typically observed using dynamic mechanical analysis (DMA) or a rubber process analyzer (RPA):

Apply oscillatory shear

Sweep strain amplitude (e.g., 0.01% → 100%)

Measure:

Storage modulus (G′)

Loss modulus (G″)

Tan δ

The Payne effect is often quantified as:

ΔG′=G′low strain−G′high strain\Delta G′ = G′_{\text{low strain}} - G′_{\text{high strain}}ΔG′=G′low strain−G′high strain

A larger ΔG′ → stronger Payne effect.

Here a nice video from MonTech (not sponsored)

Payne effect in rubber products

The Payne effect strongly influences:

Tire performance

Rolling resistance

Wet grip

Noise

Vibration damping

Fatigue and durability

Processability during mixing and shaping

For example:

High Payne effect → strong filler network → good reinforcement but higher hysteresis

Low Payne effect → better dispersion → lower energy loss (important for low-rolling-resistance tires)

What affects the Payne effect

Filler type

Carbon black vs. silica

Surface area and structure

Filler loading

Higher loading → stronger effect

Dispersion quality

Poor dispersion → larger Payne effect

Polymer–filler interaction

Silane coupling agents (for silica) reduce the effect

Temperature and frequency

Payne effect vs. Mullins effect (quick contrast)

Payne effect:

Small strain, cyclic, dynamic

Filler network breakdown

Mullins effect:

Large strain, quasi-static

Stress softening of the rubber matrix

They’re related but not the same phenomenon.

Disclaimer

Please be aware that the content on our website is provided for general informational purposes only and should not be interpreted as binding or professional advice. The information presented here is not a replacement for tailored, legally binding advice suited to specific circumstances. Although we make every effort to ensure the information is accurate, up-to-date, and reliable, we cannot guarantee its completeness, accuracy, or timeliness for any particular use. We are not responsible for any damages or losses that may result from relying on the information provided on our website.